- Home

- About Us

-

Products

-

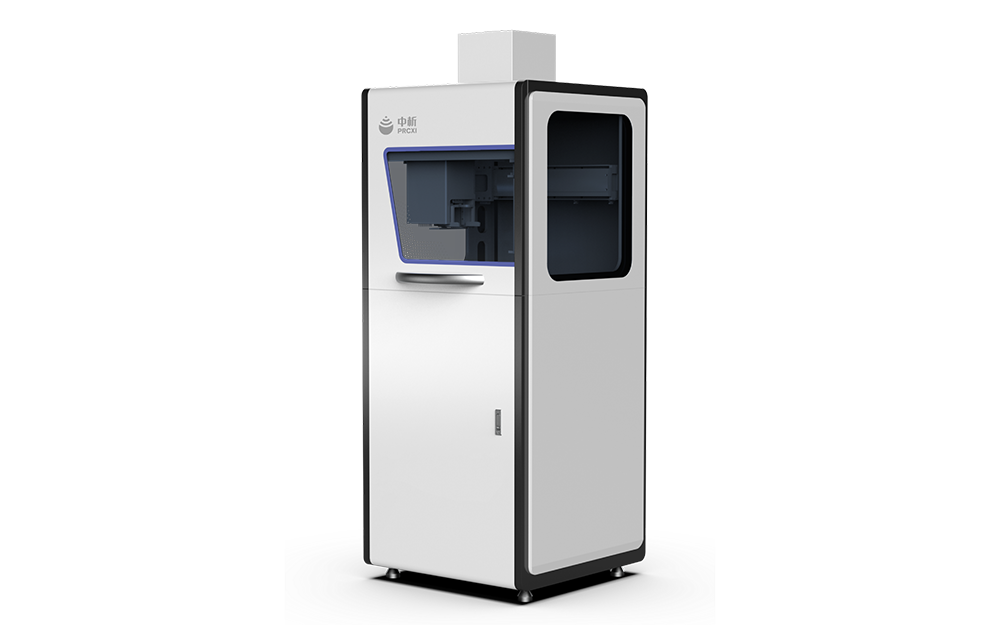

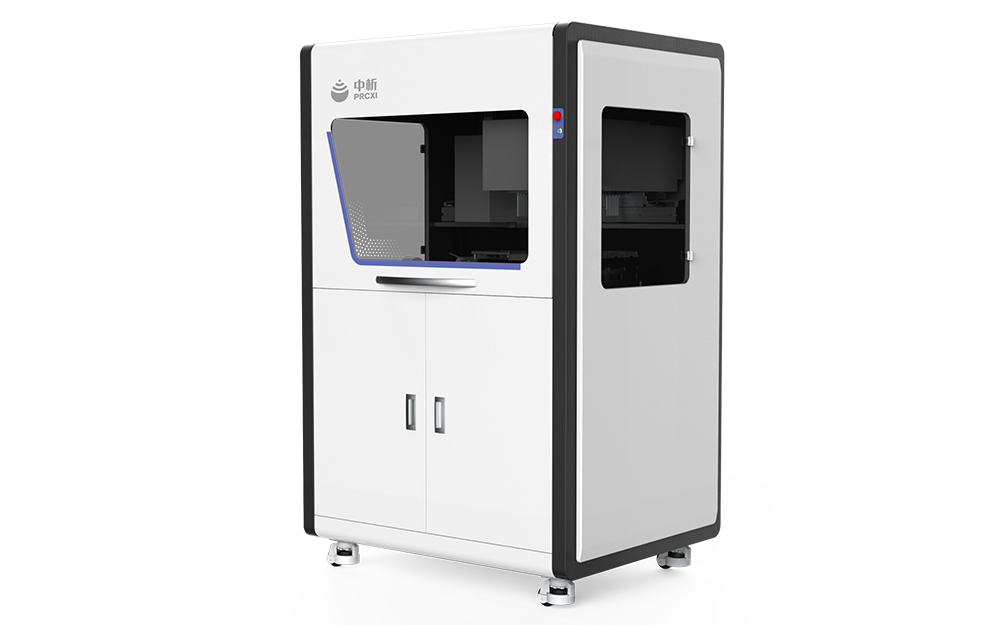

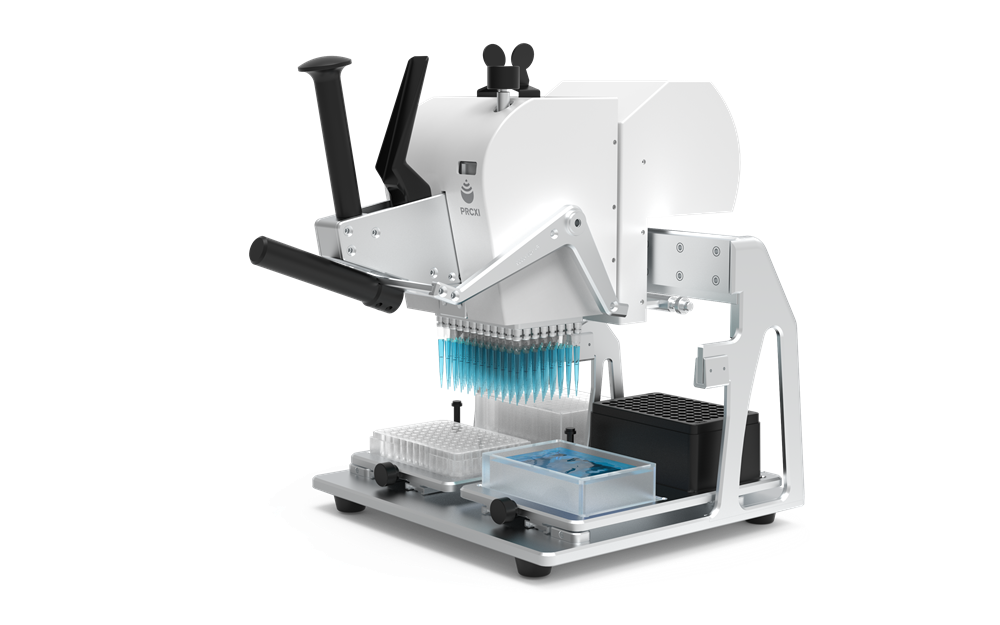

Gel Spotting And Cutting Equipment

SG9300SG9320SG9322SG9323SC9310-D72SC9310-D73

-

Genomics

SN9220SC9310-D65Ultimate 8000Hsmaster

-

Molecular Testing

SC9300 384SEST9321-1ST9321-4SC9310-D56ST9222ST9320

-

Mass Spectrometry Prepocessing

SS9320-4SC9310-D42SC9310-D27

-

Organoid Research

OrganoidStudio 1000HarvestStudio

-

Bio Bank

Immune4500

-

Synthetic Biology

SZ8000

-

Hich-Capacity Filling

SC9310-D93

-

Synthetic Biology

Transformation 1000Pickers 300Applicator 300BuildingStation 1000

-

Gel Spotting And Cutting Equipment

- Solutions

- News

- Support

- Partnerships